- Call us: +32(0)491/751.552

- vvnet@vvnet.org

cleaning and removal of organic contamination from tools and valuable metal parts

Under the umbrella of our ‘cleta’ technology, we build on our process and market expertise and on our experience in topnotch system development in the niche of ‘decontamination and reuse or recycling of metal parts and tools’, to set up and power an alliance with select partners. Together, we will be happy and proud to be your global n°1 knowledge partner and primary support in this branch, with with a modern, advanced and ecological product and service offering, and a sustainable market approach.

When it concerns delicate cleaning of high value production tooling in ploymer processing industry, or when there is a need for recovering parts from a painting or powder coating process, or even when rubber coated objects have to be denuded : our product range will show the way and we will offer you the solution that bests suits your requirements.

The activities and role of VVnet in this alliance will primarily include being involved in:

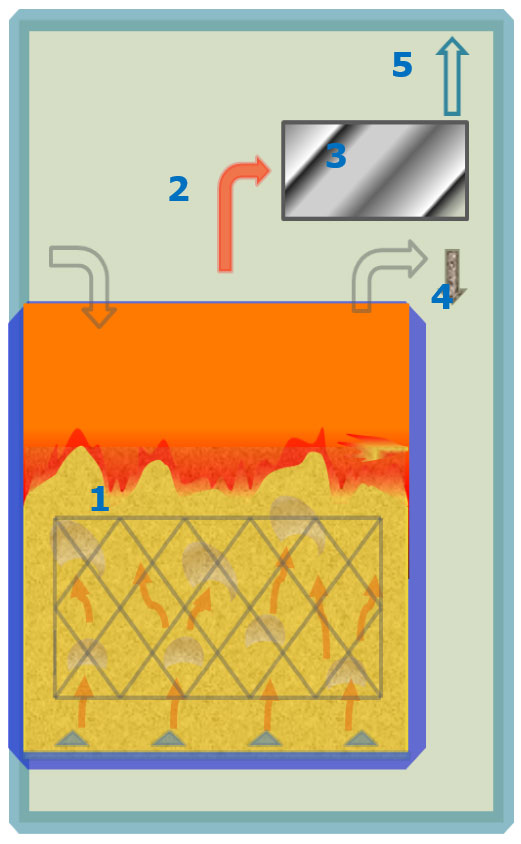

As soon as the system has reached normal operation temperature, a carrier (1) with the objects is submerged in the suspended particle reactor, as if it were a boiling liquid. The contamination on the objects will essentially convert to gas and fine inorganic powder very quickly, all while most of the energy contained in the contamination helps to heat the reactor.

Gas and inorganic powder are carried with the flow through the reactor (2), and led into a dust separation device, which can be a cyclone or a barrier filter (3).

The inorganic powder is (4) is collected and can be removed daily, and the cleaned exhaust flow (5) is released into atmosphere.

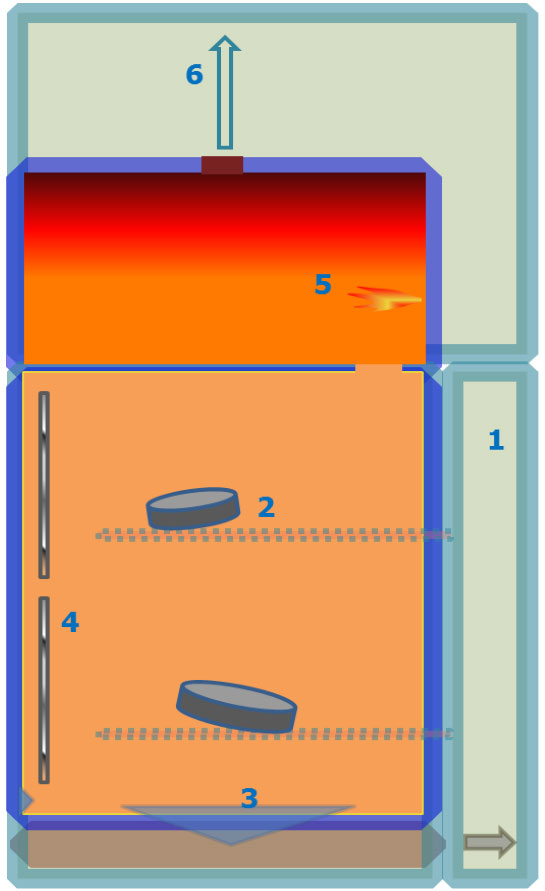

When the door (1) of the controlled atmosphere – cold or preheated - is opened, the parts can be loaded onto the stacking tray (2) which slides out of the unit automatically for easy access. Once closed, the programmed cleaning cycle starts. The process may contain a melting phase to remove most of the polymer or contamination from the delicate parts, in which case the melted material (3) can be removed prior to the start of the real cleaning cycle, or left in the unit to slowly evaporate later in the cycle.

The cleaning cycle itself takes typically 1.5 to 3 hours, depending on the parts and the quantity of polymer to be removed. The atmosphere – temperature and oxygen content - in the reactor is permanently controlled to keep temperatures right all the time and to avoid overheating or burning at all times. The reactor is electrically heated (4), and the gases leaving the reactor pass through an ignition and postcombustion chamber (5) to clean the exhaust flow (6) before it is released into atmosphere.

If not, feel free to contact us through phone or email, and we'll answer your questions to the best of our abilities.

VVnet focuses on technology, product and business development for ecological niche applications, mainly in the field of decontamination, waste or sludge conversion, aluminum treatment and gas cleaning. We are committed to develop and spread promising ‘Novel Ecological Technologies’ with an open approach, through partnership, joint-venture, license or franchise business models, create proprietary ‘niche’ technologies and develop exploitation technologies or products with strategic partners.

VVnet is created to incorporate and centralize ecology- and environment related activities, knowledge and titles from its founders or partners to exploit them in the broadest sense and to market and sell products, services and rights, directly or through participations and partnerships. Our VVnet ‘green valley’ concept lays down our intentions and expresses the green, ethic and sustainable character of all our initiatives : “Pure, simple, natural and clear”, as our mission.